A local police department recently needed shirts and approached The T Shirt Spot Los Angeles for help. The chief requested embroidered for shirts for the conference, but quickly learned that the lettering would not be legible on a hemmed shirt. The T Shirt Spot offered to print DTF transfer, which ended up being perfect for the occasion. The clarity of the logo was praised by other attendees. The T Shirt Spot's advice helped other fire departments look more professional, too.

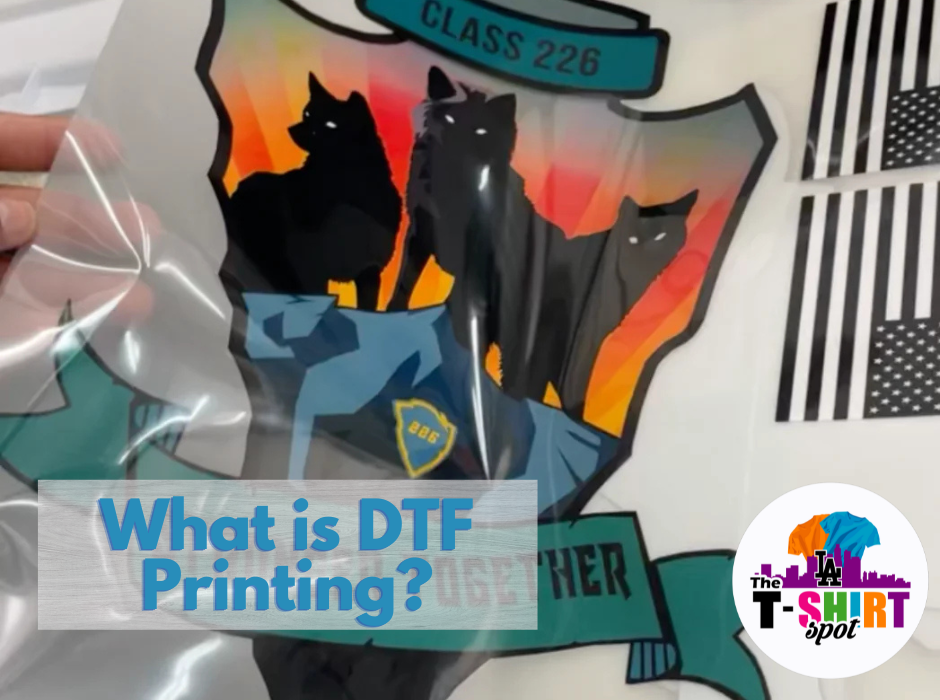

Direct to film (DTF) printing processes produce a mirror image of a print design. The image is then printed onto a PET film, which is then heat-pressed onto the garment. Next, hot-melt powder is applied to the garment using Automatic Powder Shaker. The transfer powder acts as buffer between the fabric and metal. This process is ideal for a variety of garments, including jeans sweatshirts, and t-shirts.

DTF Printing uses a PET film for the transfer process. The PET film is made of a water-based, granular adhesive powder that is placed onto a pre-pressed fabric. When the film is heat-pressed, it forms a strong bond with the fabric. This process is called curing. This step takes about 15-20 seconds and produces a durable finish. A DTF print is long-lasting, durable way to brand your clothes.

DTF Printing is an economical solution for running special-edition print goods. It allows businesses to test designs and determine which ones work best. DTF transfers should be sideline though, and only used for large-scale projects. If you'd like to learn more about DTF Transfers, check out the Supacolor website. This website allows shops to upload their artwork and receive the printed transfers. The process is easy and affordable.

DTF Printing is ideal for cycling, workwear and high-visibility clothing. DTF is water-based, which makes it perfect for use on workwear, t-shirts, and other fabrics. This process doesn't crack like screen printing, and works on almost any fabric. Depending on the fabric, DTF is an excellent option for any small business. It is fast, efficient, and profitable for any size organization.

DTF printing uses PET film and melted powder to create a transfer-guide print. Once the print is ready, the process is very easy to operate. The DTF printing process is a one-transfer process. A DTF printer can transfer the image to almost any fabric DTF is also suitable for a wide variety of fabrics. The owner of Yellow Springer Tees & Promotions, a company that offers both DTG and DTF printing, uses DTF for his small-run orders. He needed another solution because he needed another solution to sublimation for his polyester prints.

DTF Printing is a fast process. It's not perfect process, but the process is fast and efficient. And it's not all about the ink. The software is just as important. It controls the DTF printing process and influences the colors the produced. The DTF printer uses CMYK and white color profiles and it's a crucial part of the process. A DTF printer has to be able to print on both CMYK fabrics. You can